Have you ever wondered how long it takes for a heat press to reach the desired temperature? The size of the heat press plays a crucial role in determining the heating time. In this article, we will explore the relationship between heat press size and heating time, providing you with valuable insights when planning your projects.

When it comes to heating up, larger heat presses naturally take longer compared to their smaller counterparts. Therefore, it is essential to consider the size of your heat press when estimating the time it will take to reach a specific temperature. Proper planning ensures that you can efficiently manage your time and resources.

Our investigation has uncovered some interesting findings. When connected to an outlet and circuit of adequate size, including the wiring, a heat press typically takes around 15 to 20 minutes to achieve temperatures in the upper 300s Fahrenheit. This information serves as a useful benchmark for heat press users, helping them gauge the expected heating time for their specific models.

However, if you notice that your heat press is taking significantly longer than the estimated time to complete its tasks, it may be a cause for concern. In such cases, seeking the assistance of a specialist is advisable. It could be as simple as disconnecting other devices on the circuit to ensure optimal performance. Alternatively, you may need to install a dedicated circuit of appropriate size that matches the dimensions of your heat press.

When does a heat press reach its maximum temperature? The temperature is 385°F.

- 9×12 approx. 10 Minutes

- 15×15 approx. 15 Minutes

- 16×20 approx. 20 Minutes

- 16×24 approx. 20 Minutes

As with any machine, the temperature of the environment will slightly affect the heating process’s efficiency. It is important to note that when a heat press is working correctly, its average times should only differ somewhat from these average times.

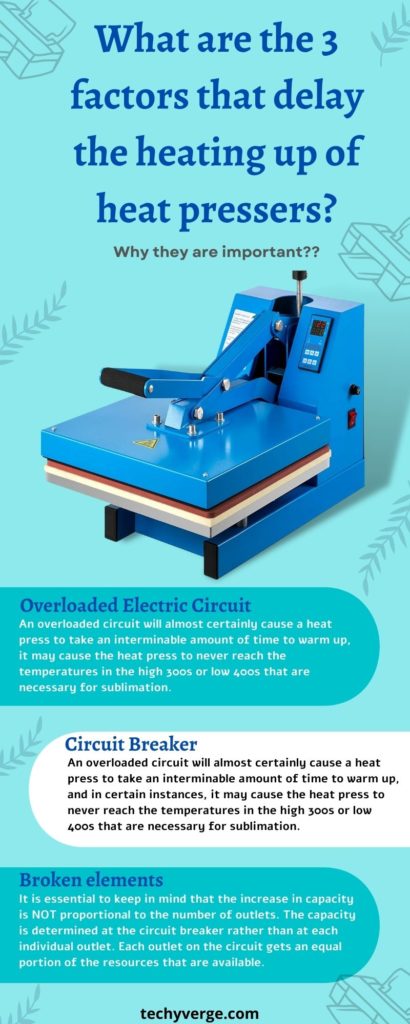

These are the 3 factors that delay the heating up of heat pressers:

It is not unusual to find a heat press that takes 20 minutes to heat up, which is pretty close to the average.

There may be a problem with your setup or the heat press itself if your 16*20 heat press takes 45 minutes to heat up in an otherwise unfrozen room.

It is common for a heat press to take FOREVER to reach the proper temperature for various reasons.

The average heat press takes about 15 minutes to heat up. Depending on the size and temperature of the heat press, this can vary.

3 Common Reasons Why Heat Presses Might Take a Long Time?

We want to believe that a heat press is as simple as plugging it in and turning it on.

Still, the truth is that they need a significant amount of power for them to function correctly, particularly when we get up to larger sizes such as 15×15 and 16×20 and beyond.

The truth is that the larger the heat press, the greater the amount of watts required, and the greater the likelihood that you will struggle to get it to reach the desired temperature at an appropriate time.

If the performance of your heat press is not what you would anticipate, there are three things you may look into, according to our expertise.

There are three primary factors that contribute to a heat press taking an unacceptably long time to heat up:

- Overloaded Electric Circuit

- Circuit Breaker That Is Too Small

- Broken or Damaged Heating Elements

Let’s start with the easiest and work our way up to the most difficult. A heat press’s sluggish heating might be the result of overloaded circuits.

An overloaded circuit will almost certainly cause a heat press to take an interminable amount of time to warm up.

In certain instances, it may cause the heat press to never reach the temperatures in the high 300s or low 400s necessary for sublimation.

If your circuit is of a suitable size and properly linked, fixing this issue should not be difficult at all.

Each circuit in your electrical box can only handle a certain amount of power. Everything connected to outlets shared on the same circuit will need a portion of the available capacity.

The power to heat your heat press will decrease proportionately as the number of plugged-in products increases.

Resolution

While working with your heat press, you should disconnect anything possible on the circuit. Your heat press will be the only appliance on the circuit that requires electricity and draws watts from it if you do it this way.

It will take a lot less time to heat up if your heat press doesn’t have to compete for resources (available watts) with other home electronic devices, such as your printer, computer, lighting, or radio.

If the issue persists, you may have a more significant problem with the load that the heat press is putting on the circuit in comparison to the capacity of the circuit.

Amps of the Circuit Are Insufficient for the Heat Press

The fact that our bigger heat presses use a significant amount of wattage is the root cause of most of the issues customers report about the timely heating of their larger heat presses (power).

Watts are the units that devices use to measure their consumption of the power that is made accessible by our circuit.

Watts, also known as watts, is usually indicated on the product box or the manufacturer’s website.

The majority of domestic arrangements

The vast majority of outlets used in homes and the circuit breakers that accompany them are rated for 15 amps, 110-120 Volts, and 1800 Watts.

To reiterate, we said “most,” so please don’t assume that this rating applies to the outlets and circuits in your home just because we said “most.”

It is essential to remember that the increase in capacity is NOT proportional to the number of outlets.

The capacity is determined at the circuit breaker rather than at each outlet. Each outlet on the circuit gets an equal portion of the available resources.

To Complicate Matters: It is suggested that outlets and circuits be used for no more than 80 percent of their rated capacity at any time.

This is done for safety reasons. Because exceeding circuit restrictions might pose a safety risk, and because the available amps, volts, and watts are not guaranteed to be precisely 15, 120, or 1800, it is important to avoid doing so.

A specific circuit breaker rated for 15 amps may have real limitations of only 14 rather than 15. In addition, the wattage used by a heat press may be higher or lower than what is indicated.

They manufacture devices that measure your real current; however, with both of these factors, it is simple to comprehend the rationale behind the recommendation to use a circuit’s capacity no more than 80 percent of the time.

What Wattage Should Be Used for Larger Heat Presses?

Several heat presses utilize between 1400 and 1800 watts, and some even use more!

Even while it will be more expensive for us up front, if you have the choice of purchasing a unit that uses fewer watts for the same size, we believe it is worthwhile.

Let’s examine the difference in wattage between two different 15×15 heat presses.

For instance, we have this 15 by 15-inch MPress heat press from HPN, and it has 1400 watts of power on the lower end of the spectrum.

Compare this to the 15×15 press sold by Fancier Studio, which, according to the product description on Amazon, consumes a staggering 1800 watts of power.

Now, let’s contrast these two distinct heat presses in the context of a typical domestic setting.

Let’s assume you have a standard 15-amp breaker, which has a capacity of 1800 watts and can only handle that much power.

If you are concerned about safety and adhere to the suggested load of 80 percent of the circuit’s maximum wattage, then you only have 1440 watts available on that circuit (1800x.80).

You can still use an additional appliance or light in addition to the MP Heat Press if you choose to use the heat press included with the press.

If, on the other hand, you went with the FancierStudio, you would be exceeding the 80 percent safety limitations even if you did not connect to any more devices. (follow this link to access the FancierStudio).

Because of this, a preliminary study on your power capability is vital. Both of these presses are quite good. One is more costly, but the other will need more electricity (power you may not have).

Resolution

To begin, you might consider purchasing heat presses with a lesser wattage, mainly when they are the same size.

They will need more money upfront, but there is a good rationale for why they are more expensive overall. And I hope that you are starting to understand the distinction.

Second, suppose the desired heat press has a maximum capacity higher than the recommended maximum, such as 1800. You should consider having a trained professional construct a dedicated 20 amp circuit in that case.

A trained technician will be able to inform you whether or not your electrical panel has a place for this addition, as well as whether or not any improvements are necessary.

Each of our enormous heat presses will have its own dedicated 20 amp circuit in our workshop, along with wiring of the proper size.

Upgrades to 20-amp circuits or outlets require rewiring the building to convert a 15-amp course to a 20-amp circuit.

It will be necessary to switch everything, including the outlet, the circuit breaker, and the wiring.

Why Should You Upgrade Your Heat Press with a Dedicated 20 Amp Circuit?

A completely converted 20 amp circuit (outlet+breaker+wires) has a capacity of 2400 watts, and 80 percent of that capacity is 1920 watts. The “safe cushion” is also known as the “safety cushion.”

That is an ideal power supply for our big format presses, which need a demand of 1500–1800 watts.

If none of those mentioned earlier factors is to blame for the length of time it takes for your heat press to reach the desired temperature, the problem may be caused by a malfunctioning element.

Broken or Damaged Heating Elements

Essentially, it means a break in the electrical connection or heating channel inside the heating element that flows through your press’s top plate.

The burners of an electric stove are the most suitable analogy we can supply.

Imagine one of those circular heating coils that lights red and, one day, a break occurs, and you can see that a portion of the element no longer glows red.

It will still become heated due to heat transfer, but the location previously responsible for heating things is no longer the case.

If the heating components in your device get damaged or malfunction, not only will it take an extremely long time for the press to reach the desired temperature, but the results of any pressing done with it may not be satisfactory.

The Procedure for the Exam

You will be able to determine with the assistance of a laser thermometer whether there is a break in the heating element or not.

Let the machine for around 15 minutes to warm up, and then use the laser to take temperature readings in a few different spots to determine the overall temperature.

Resolution

If your device allows for the interchangeable replacement of components, you should get one without hesitation. When compared to replacing the whole machine, it is far more cost-effective only to replace the top heating element.

If, however, you’ve never really liked your heat-press, to begin with, and it does feature a swappable element, it may be time to consider upgrading to a higher-quality one that comes with superior technical support and a longer guarantee.

Watching this video from HPN (link to video) will assist you in selecting the appropriate size heat press for your needs. We strongly encourage doing so.

Conclusion

Understanding how long it takes for a heat press to heat up is crucial for both new buyers and those considering a replacement. By revealing the heating times for various sizes of heat presses, we aim to provide you with a valuable benchmark to guide your decision-making process.

If you find that your heat press is taking longer than usual to heat up, it’s important to identify the underlying cause. This article has shed light on the potential reasons and offered possible solutions. By taking the necessary steps, you can ensure efficient and effective heat press operations.

In summary, knowing the heating time of your heat press is vital. Whether you are a beginner or an experienced user, this information empowers you to plan your projects effectively. Now, let’s delve into the results of our investigation and uncover what might be causing your heat press to experience longer heating times than anticipated.

The heating time of a heat press can vary depending on its size. On average, it takes around 15 to 20 minutes for a heat press to achieve temperatures in the upper 300s Fahrenheit.

Yes, the size of the heat press does impact the heating time. Generally, larger heat presses take longer to heat up compared to smaller ones.

If you notice that your heat press is taking longer than expected, it is advisable to consult a specialist. They can help troubleshoot the issue, which may involve disconnecting other devices on the circuit or installing a dedicated circuit of appropriate size.

Understanding the heating time of your heat press allows you to plan your projects more efficiently. It helps you allocate the right amount of time for heating and ensures optimal use of resources.

While heating time is an important consideration, it is not the sole factor when choosing a heat press. Other factors like press size, temperature control, and overall performance should also be taken into account.

The heating time of a heat press is primarily determined by its size and wattage. While it is not recommended to tamper with the heating elements, ensuring proper electrical connections and using an appropriately sized outlet can help optimize heating efficiency.

- Can You Sublimate on Nylon and Polyester? Which oneis the Best - February 19, 2024

- Converted Epson Eco Tank Et-2800 Vs Et-2803 Sublimation Printer [Review 2024] - February 19, 2024

- Can You Reuse Sublimation Prints? (The Righ Answer) - February 19, 2024

![Top 100+ FAQs Related to Sublimation Printing & Heat Press [Updated 2024] faqs related to sublimation Printing](https://www.techyverge.com/wp-content/uploads/2022/08/faqs-related-to-sublimation-Printing--150x150.jpg)