How Can You Sublimate on Cotton is one of the burning issues because sublimation is the need of the hour. Sublimation printings on nearly all the materials are possible. However, sublimation on cotton is a relatively lengthy and challenging process. People do not know anything about the sublimation of this kind of material.

Sublimating cotton with heat transfer vinyl is one of the best methods of sublimating cotton. In addition, unique sublimation fabrics can be applied to cotton to enhance the bonding of the natural fibers with the sublimation dyes. This presents an excellent solution for sublimating cotton. Also, look at the How to sublimate on cotton sweatshirts.

Cotton is not similar to polyester. Therefore, it cannot absorb or store ink for printing. Thus, its user always has to put on some coatings or adjust some conditions for this process to take place.

Sublimation on cotton provides you with many best quality designs. This cotton material may be in the form of T-shirts, bags, and even mats.

Moreover, they are also used in printing nearly every type of fiber-manufactured material. We will explain all the significant processes and tips that play a major part in this process. For this purpose, you must first know what is required for this cotton sublimation process.

What’s Required for Cotton Sublimation?

There are many things and products that you need for this process. We aim to provide you with information on some of the most valuable products related to this process.

1. Transfer Papers

The first thing you need in this sublimation process is the use of the best quality transfer papers. These sublimation transfer papers help you create your creative designs on cotton materials.

We will strongly recommend you use FOREVER Subli-Light transfer papers. These unique transfer papers help you to easily transfer your design through the heat press on the surface of your cotton material.

2. Sublimation Printer

Using the perfect quality printers helps you create the best and cool designs. If you are not using suitable sublimation printers, your printed design can’t have a delightful and attractive look.

It will be better for you if you use the sublimation printers of Epson and Sawgrass. Due to their features and functions, they are ideal. Thus, they can perform their functions without any problem.

3. Colour of the Material

The sublimation printing process can only be performed on light-colored materials. The reason is that its ink can not bind to the surface of dark-colored materials. But, if you are still using dark-colored materials, your design will not be as attractive as it should be.

4. Heat Press

The following product on the list is the most important thing in creating your designs. It generally presses both ink and the sublimating material together. So, a permanent impression of design can be created.

High pressure and temperature are present during this pressing process. Your design is pressed for a total of 400 F for about 60s. For this process, it will be better than using a heat press such as Insta 1020.

5. Software Programs

Every sublimation printer provides the best software programs that automatically control the entire sublimation process.

You must install these software programs on your device to sublimate cotton materials. Any device can download them easily. Some of these programs include Photoshop, Creative studios, and Illustrator.

Process for Sublimation on Cotton

Here are some major steps you need to follow to create the best quality cotton designs.

1. Create your Design

The first important step in this process is to create your design. It can be made using hands, machines, and even software programs. The best idea will be to use Subli-Light transfer papers for your design forever.

These papers will fully support both your printer and creative art design. Moreover, it gives you thousands of different colors and shades to use in your designs. The internet also allows you to choose your design without paying any money. When your design is completed and ready to be printed. You must place it on the transfer paper.

2. Print your Design

The next step is very simple. You have to place your design on the transfer paper. But, it is essential to place face-down concerning the heat press.

This is because the heat press can only print one side of the paper. If the transfer paper is not placed face-down, your design will not get printed. You can use different branded printers to do this process.

3. Heat Press

Before you transfer your design to your cotton material, you should first heat press it for about 30 minutes. This process will only occur if you place your transfer paper straight into the heat press and cover it with a silicon paper sheet.

Now, for printing your design on your cotton material. You should press your material through the heat press at about 350 F. This is to cause the majority of your design to be sublimated on your cotton material’s surface.

4. Using the Finishing Paper

In the previous step, your design was sublimated on your cotton material. But, it was not permanent and could wash or fade away. To cover this problem, we heat-press our cotton material again with the finishing paper for the 30s.

This causes the design to attach to our cotton material’s surface permanently. We are making our design to be perfectly sublimated. Now, there is no chance for the sublimated design to fade or wash away.

Guideline for Cotton Sublimation

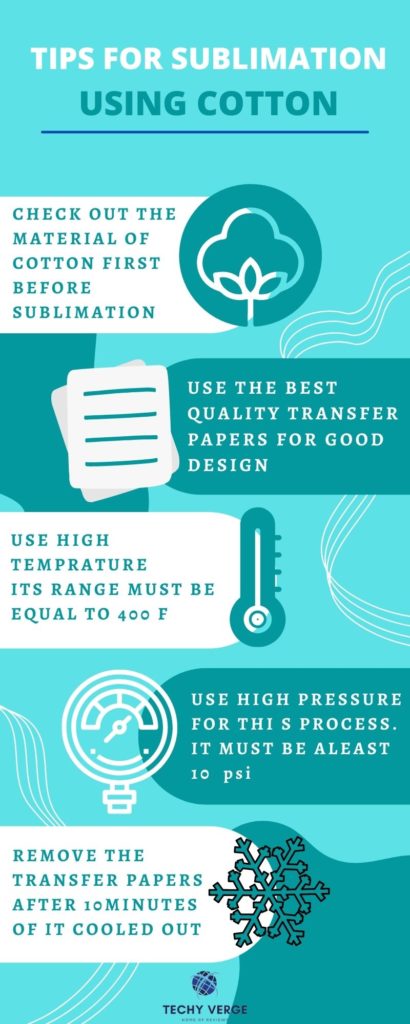

Now, let’s talk about some of the most important tips you can use in this cotton sublimation process.

Our guidelines will help you complete cotton sublimation easily without significant problems.

1. Check the Cotton material

When you are about to sublimate any material, material type plays an important role in your project. If it is cotton, you should first heat press or pre-test this fabric.

This will allow the fibers of the cotton fabric to open up. As a result, sublimation ink can easily form chemical bonds with the surface of the cotton material.

2. Use the best quality transfer papers

The second tip is the most special one in this cotton sublimation process. If you want your design to be perfectly sublimated on cotton material, you should use the best quality transfer papers.

By using these transfer papers, your sublimation ink can be fully absorbed. Therefore, you can also sublimate to dark-colored materials.

3. Use high temperature

When sublimating the cotton materials, the main thing you should be keeping in mind is the use of high temperatures. The reason for this is that cotton usually has a higher melting point than any other kind of fabric.

Therefore, you have to choose a relatively high temperature for this process. This temperature should range from 400-430 F.

4. Use less pressure

The next main tip that you should know in this cotton sublimation process is the use of less pressure. The lesser pressure, the more suitable the printing will be. Therefore, it is advised to set the pressure of your heat press between 10-20 psi.

5. Removing the transfer paper

The last major tip for this process is the proper removal of the transfer paper. You should never peel off this paper just after the printing process. The reason is that the paper is still hot at this time, and it may not peel off properly.

It is, therefore, advisable to wait at least ten minutes before continuing. So, it may cool down and can easily be peeled off.

Cotton Sublimation FAQs

The SG1000 sublimation printer is said to be the best cotton sublimation printer. The size of the heat press used in it is 15×15. That can easily sublimate cotton materials.

The Siser EasySubli transfer papers are the most versatile for cotton sublimation processes. These transfer papers can absorb and transfer sublimation ink at a high rate.

Sublimation on cotton is only possible with the use of Heat Vinyl Transfer sheets. These sheets form the outer coatings of cotton materials and help it absorb more ink to make the best quality output designs.

For sublimating cotton materials, it is advised to use your heat press at 400 F. Moreover, you must press your cotton materials for about 50s to print out the best quality designs.

Conclusion

We tried to inform you about the cotton sublimation processes and their tips. This means you won’t have to worry about anything anymore.

However, if you ask us what can be the best printer for the cotton sublimation process, we will strongly recommend using the Epson WF-7710.

- Can You Sublimate on Nylon and Polyester? Which oneis the Best - February 19, 2024

- Converted Epson Eco Tank Et-2800 Vs Et-2803 Sublimation Printer [Review 2024] - February 19, 2024

- Can You Reuse Sublimation Prints? (The Righ Answer) - February 19, 2024

![Top 100+ FAQs Related to Sublimation Printing & Heat Press [Updated 2024] faqs related to sublimation Printing](https://www.techyverge.com/wp-content/uploads/2022/08/faqs-related-to-sublimation-Printing--150x150.jpg)